IN-SITU RECOVERY

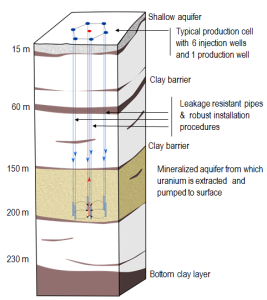

In-Situ Recovery (ISR) is a proven method of extracting uranium from sandstone-type uranium deposits that cannot be mined using the conventional open-pit or underground mining technologies. Suitable conditions for ISR mining mean that the geological formation containing the uranium, mainly sandstone layers, must be permeable enough to allow the leaching solution to circulate throughout the mineralized layer and at the same time be isolated from underneath and above aquifers by impermeable clay layers. Without these two geological conditions, it is not possible to use this technology. Zuuvch Ovoo deposit meets the conditions necessary to be exploited by ISR technology, the most popular method for low-grade uranium deposits.

•More than 60% of the world’s uraniumis mined using ISR (source: WNA)

•ISR mining has tripled its share of uranium mining production since 2000

UNDERSTANDING ISR

The ISR method consists of injecting a leaching solution into the deposit via injection wells to recover the uranium contained in the rock. The solution containing the uranium is then pumped back up to the surface via pumping wells and sent to a processing plant, where the uranium is selectively separated from the solution, purified, dried and calcined to get a final form of the saleable product consistent with market standards, which is then packaged as in a conventional processing plant.

The uranium-free leaching solution is then reinjected into the deposit. In situ mining is a closed “plant-wellfield-plant” loop. By using the ISR method, uranium-bearing ore is extracted by dissolving only the metal without bringing the ore to the surface.

ADVANTAGES OF ISR

ISR has become a popular method because it has environmental and economic benefits over conventional open-pit or underground mining. These include:

– No creation of open pits, waste dumps or tailings: the landscape remains the same over the life of mine.– Minimal use of heavy equipment, no haulage road, minimal noise, dust and diesel emissions.

– No blasting, no earth-moving, no ore-crushing, therefore no dust is generated.

– No mining fleet, no ore-crushing, simpler processing plant.

– Greater flexibility in production capacity.

– No mine dewatering: water consumption is about 3-5 times less than usual mining technologies.

CONDITIONS FOR ISR UTILIZATION

The ISR method can be used to extract low-grade uranium deposits when geological conditions are suitable.

- The geological formation (deposit) containing the uranium, mainly sandstone layers, must be permeable enough to allow the leaching solution and recovery solution to circulate through the mineralization.

- The deposit must be confined between 2 waterproof layers (clay layers) to recover the circulating solution

- The leached aquifer must have no connection with other aquifers

- The deep aquifer that contains the uranium ore-body is naturally rich in salt, metals and uranium, reflecting the fact that the groundwater is not drinkable

GROUNDWATER PROTECTION PRINCIPLES

The major environmental issue associated with ISR is the protection of groundwater. The following groundwater protection principles apply:

– The local groundwater system is fully mapped prior to ISR mining

– ISR mining should not compromise a water resource usable for drinking purposes

– At no stage should ISR mining compromise groundwater use in the mineralized aquifer outside an agreed distance (not exceeding a few kilometers)ISR mining should not affect other aquifers present in the mining area. No communication with others aquifers is carefully checked prior decision to mine

– Control wells are positioned within and around the extraction area to monitor groundwater flow and quality during operation

– After remediation, the post-mining groundwater quality should be returned to its pre-mining class of usage